| SpaceClaim Online Help |

|

The Analyze group contains tools for checking the thickness of a mesh and checking for overhangs. Thickness and the presence of overhangs are things that need to be considered for 3D printing.

Thickness is important for planning 3D printing. The Thickness tool lets you measure the thickness based on facet normals or relative to the printer vertical direction.

or use the default value.

or use the default value.

You can also click the arrow to open a slider for setting the Minimum thickness. The Thickness display changes dynamical as you drag the slider.

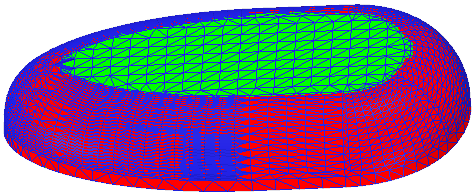

The results are shown shaded with areas that are less than the Minimum thickness shown in red. An example is shown below.

Overhanging geometry is an important consideration in 3D printing because it may require special supports. This can add cost and setup time to the process.

The Overhangs tool detects and highlights areas of the mesh that protrude out at angles up to 90°. You can set the Overhang Angle option to look for any angle up to 90°.

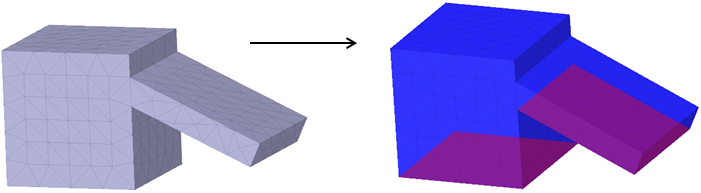

In the example below, the overhang is at 65°. The Overhang Angle is set to 64°.

© Copyright 2016 SpaceClaim Corporation. All rights reserved.