Printing the model could take a long time and a lot of material, if the entire

volume is filled.

Infill lets you shell the interior of a model and add an internal support

structure. This provides strength while reducing material costs and printing

time.

The tool has several options for controlling the size, shape and percentage of

the volume filled.

To shell by adding an infill using basic shapes:

- Select the Shell tool.

- Set the Thicken direction to

Inside.

- Set the Thickness of the shell wall.

-

Choose whether or not to keep the original faceted body after it is

shelled.

- Choose the Basic option.

-

Select the faceted body to shell.

-

Choose an Infill Shape.

Use the drop-down list to select a group: Extrusions, Lattices, or

Minimal Surfaces.

Select a desired infill shape.

-

Set the Infill Size options.

- Adjust the Preview.

- Choose a Preview Direction (X, Y, or Z).

- Use the Offset slider to move the preview section

along the Preview Direction.

- Click the Reset button to go back to the original

Offset location.

- Click Complete.The Shell is added and a new Faceted Body is shown in the structure treedesign tree.

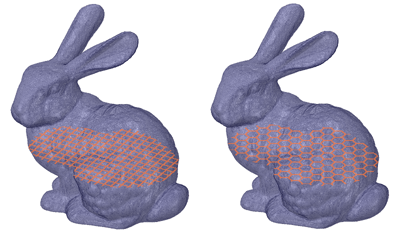

The images below show preview for Square and

Hex Infill shapes.

The Y-axis is chosen for the preview Direction and the Offset was adjusted to

place the preview near the middle of the model along the Y-axis.

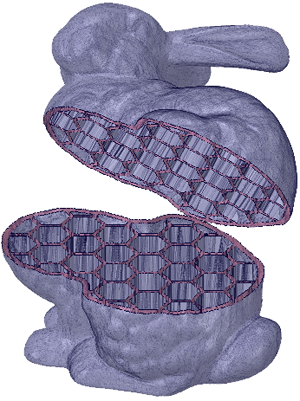

The image below shows the model shelled with a Hex infill.

The body was split and moved to expose the Infill.

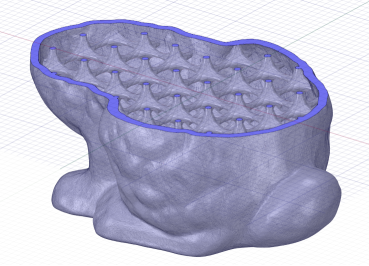

The image below shows the model shelled with a 3D lattice

infill.

Note: Lattice infills are sensitive to the coarseness of the

faceting. Coarse facets produce lattice infills faster. Coarseness is controlled

when you convert a solid body to a faceted body using the

Convert tool. When converting, use a Maximum Angle in the

neighborhood of 30° to get fewer facets and speed up the lattice

calculations.